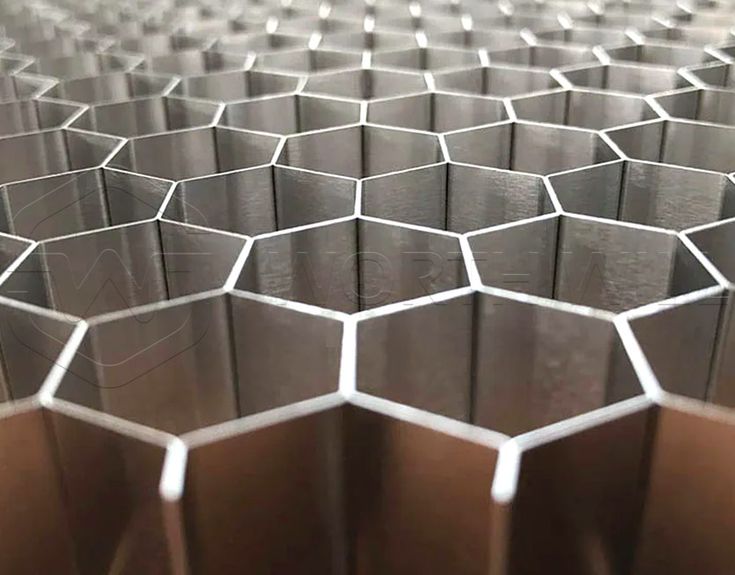

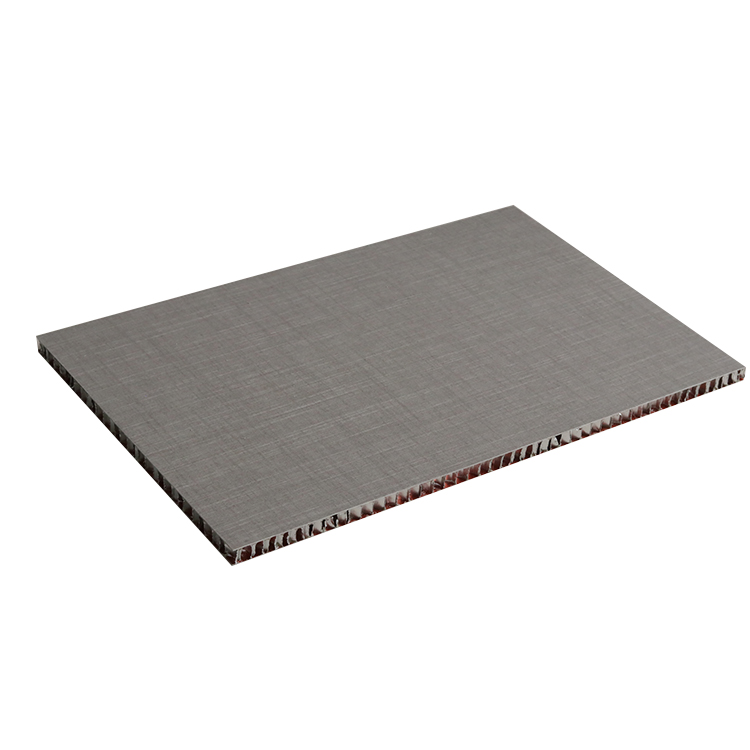

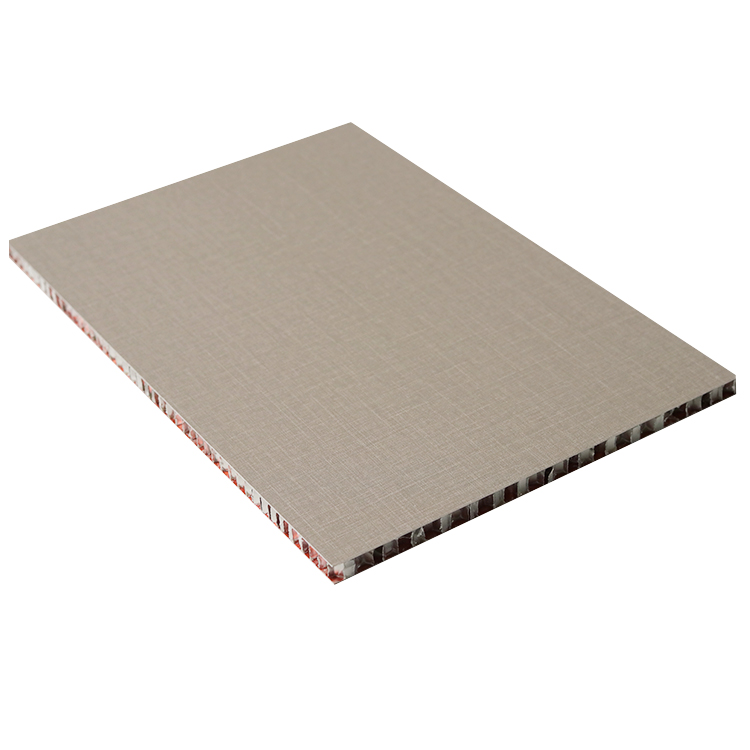

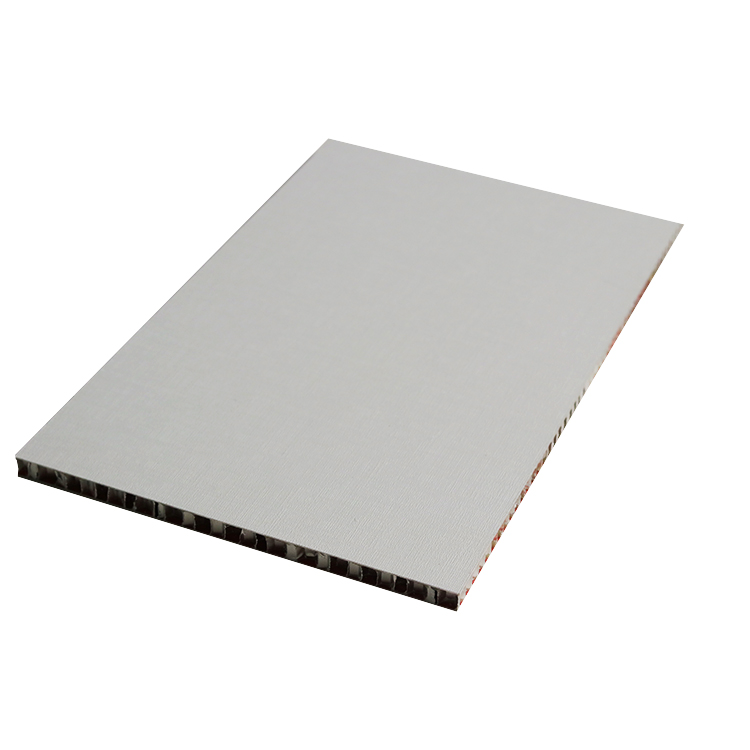

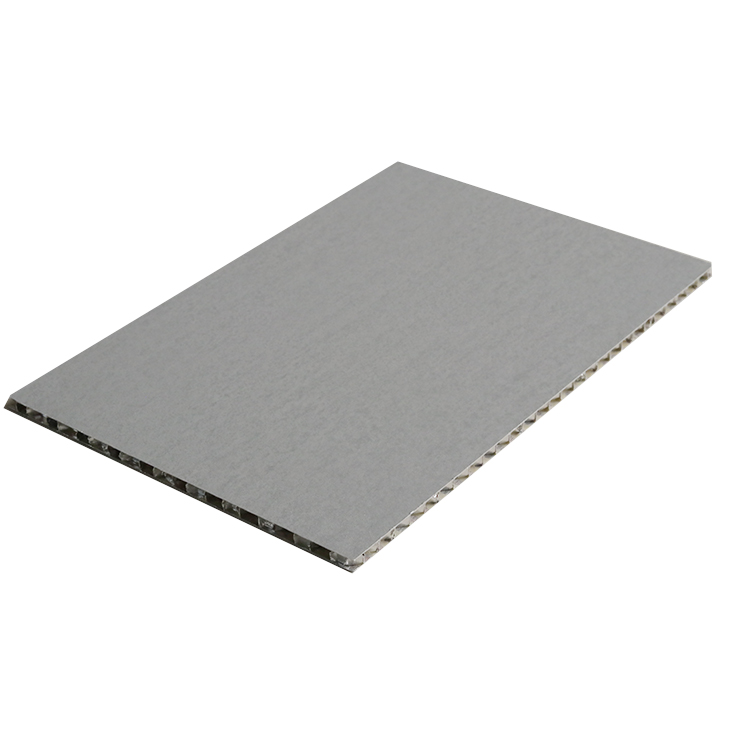

Aluminum honeycomb panels are a type of high-performance, lightweight building material widely used in civil construction, marine decoration, and other fields. They are an application of aerospace materials in the civil construction field, characterized by their light weight, high strength, and excellent durability.The panels are primarily made of high-quality 3003H24 alloy aluminum or 5052AH14 high manganese alloy aluminum. The panel thickness ranges from 0.8 to 1.5 mm, with a fluorocarbon roll-coated or high-color-resistant baked paint finish. The core material is a hexagonal 3003-type aluminum honeycomb core, with an aluminum foil thickness of 0.038 to 0.04 mm and a side length of 4 to 6 mm. The core is made using roll forming technology and is bonded to the front and back skins using a two-component polyurethane high-temperature curing adhesive .

1. Lightweight: Aluminum honeycomb panels are significantly lighter than traditional materials such as aluminum sheets and steel plates, with a weight of only 6 kg/m² for a 15 mm thick panel .

2. High Strength and Stiffness: The hexagonal honeycomb core distributes pressure evenly, ensuring high flatness and stability even for large panels .

3. Excellent Insulation and Soundproofing: The closed honeycomb structure effectively blocks the flow of air, providing good thermal and acoustic insulation .

4. Fire Resistance: Made of non-combustible aluminum, these panels meet fire safety requirements .

5. Environmental and Energy-saving: Aluminum honeycomb panels are 100% recyclable and have a long service life, making them an environmentally friendly choice .

Core density:3*3, 4*4, 5*5, 6*6

Skin panel:0.12mm, 0.2mm, 0.3mm, 0.5mm, 0.65mm, 1.0mm

Standard Dimensions: Common dimensions include widths up to 1200mm, lengths up to 6000mm, and thicknesses as specified.

Fire Rating: A1 grade (GB/T) .

Formaldehyde release amount: 0.012g/cubic meter